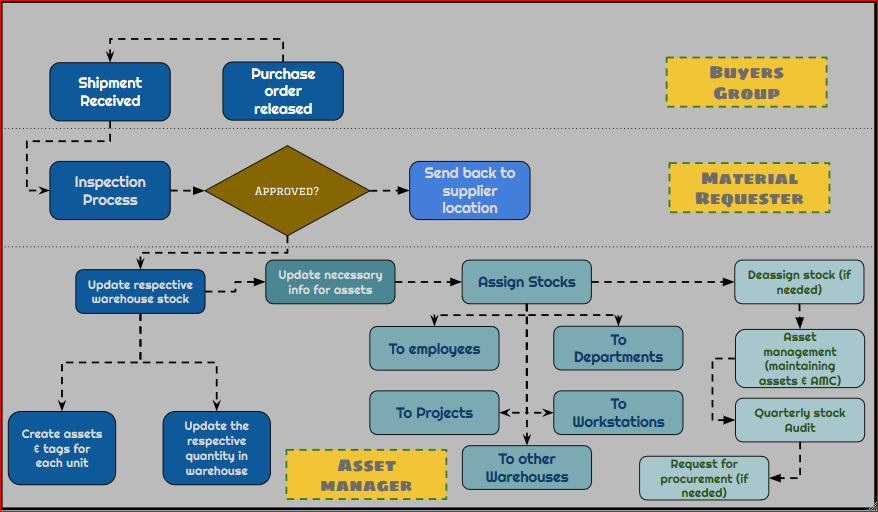

Above image shows the Inventory Process

Odoo Inventory Management can simplify redundant processes.

- Receive Goods: Odoo can efficiently monitor the receipt of ordered goods. We can handle partial deliveries, and keep track of items that are still to be delivered in the orders, and the reminders can be generated automatically for the undelivered goods.

- Inspection Process: At the time of incoming shipment the goods can be brought to a temporary inspection level and checked at this point of time. Once the inspection is completed, only the quality goods can be approved and brought into the stock, while the rejected will be going back to supplier.

- Internal Transfers: Once the goods are IN STOCK, they can be transferred from one to many internal locations (should be defined) like different warehouses using internal stock moves.

- Scrap: Damaged goods can be moved to scrap locations which will not reflect in the stock.

- Lots: Shipments can be made in terms of Lots or Batches where any incoming shipments can be tagged to defined lots and then the goods are sold or utilized based on the Lot numbers

- Tags: Tags can be created for all the products and barcodes can be generated based on the tags. These barcodes can be printed and attached to the products so that they can be read by using the barcode scanners.

- Product Types: Different types of products can be maintained in inventory like, Stock able, Consumable, Service, Expense or Assets.

- AMC: Annual Maintenance Contracts for the Asset products can be tracked based on the expiry dates and renewal can be done after receiving the notifications.

- Reordering: Reordering level can be set to the stock for individual products and reminder notifications can be sent once a product reaches the reordering level.