Project Objective

To implement a fully integrated Sales → Manufacturing → Delivery → Installation workflow in Odoo 18 that automates:

Sales Order-driven manufacturing & purchasing,Milestone-based project tracking,Multi-plant manufacturing with intercompany flows,Detailed inventory traceability with LOT & Serial numbers,Financial tracking across units and plants,CRM-driven lead-to-order process,Field Installation project management,Quality, Maintenance & Helpdesk workflows

Business Challenges

- Manual, disconnected processes across Sales, Manufacturing, Procurement, Installation.

- No visibility of milestone progress vs actual dates.

- Limited inter-company automation (multi-GST units).

- Complex BOM & job tracking requirements.

- No structured traceability of LOT/Serial-based components.

- Inventory scattered across locations with poor reordering visibility.

- Non-standard financial reporting — lacked plant-wise P&L and cost center tracking.

Solution Overview

A deeply customized Odoo 18 Enterprise system was implemented, covering the full process lifecycle:

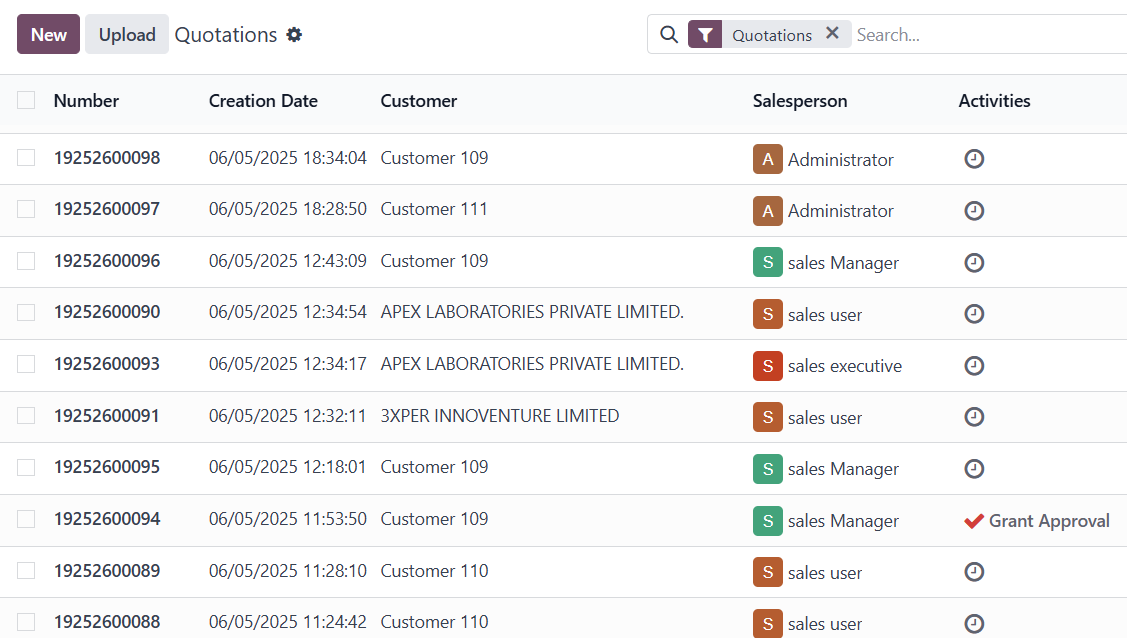

Sales & CRM

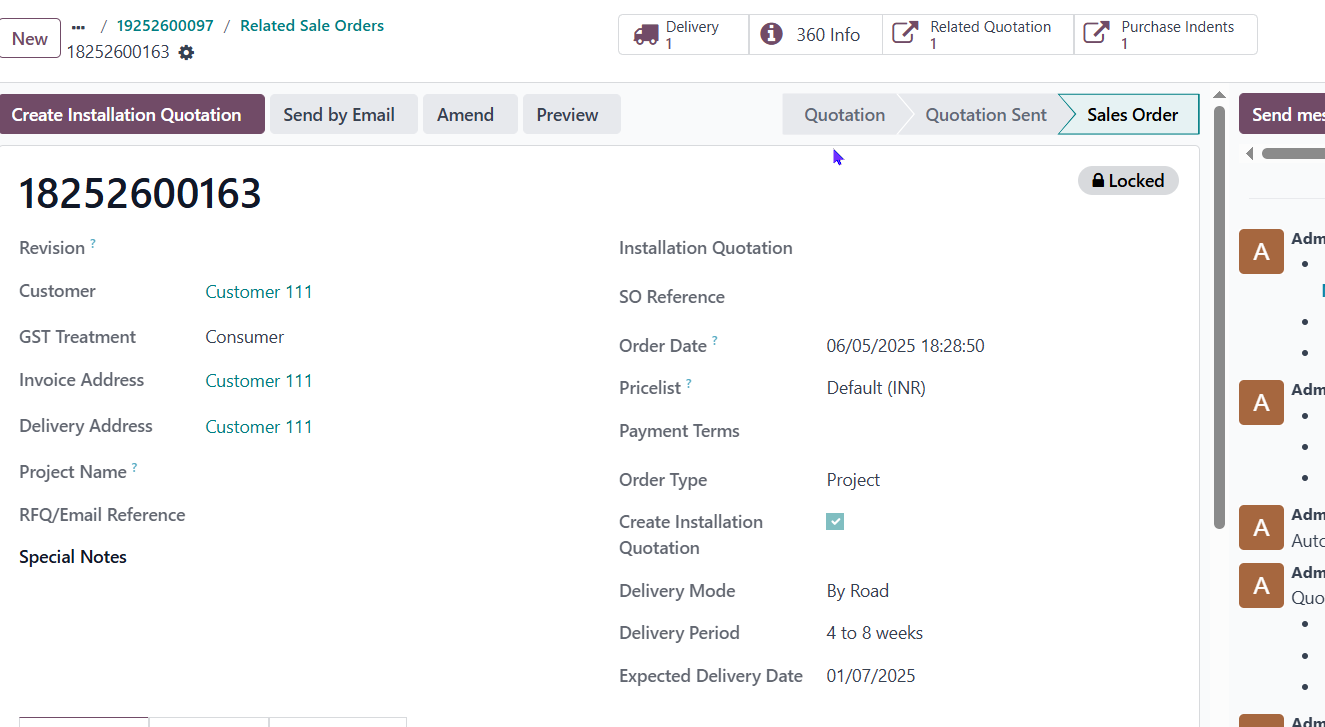

Quotation → Sale Order → Manufacturing Trigger automated:

- Confirming a Quotation creates a Sale Order → triggers Manufacturing Orders and Purchase RFQs.

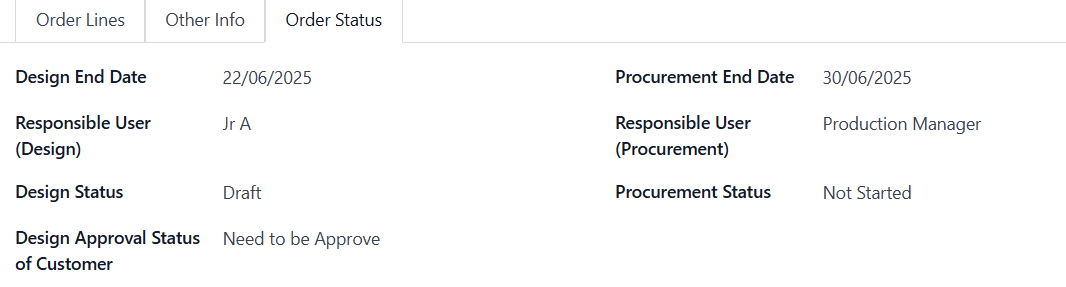

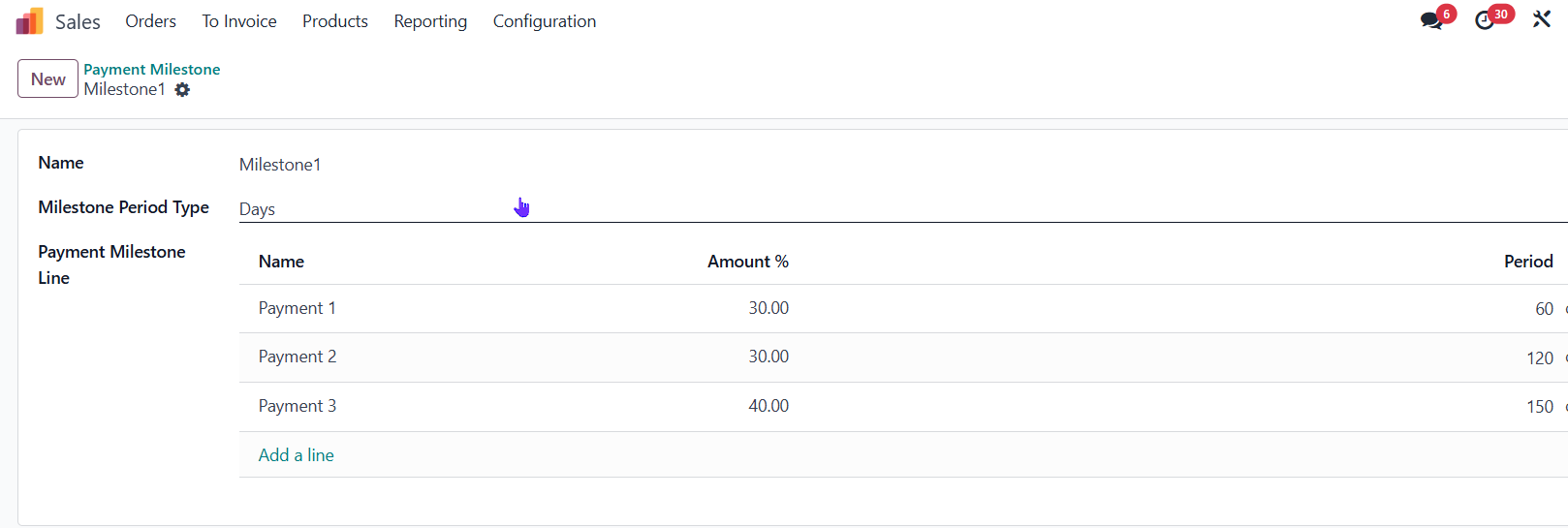

Milestone-driven delivery planning: - Automatic milestone calculation based on Product/Category/BOM Lead Times.

- Actual vs Planned milestone tracking visible in Sale Order

- Automated Alerts for overdue milestones — sent via internal Odoo Channel (“Pending Order Tracking”)

- Daily Pending Order Status Report auto-generated:

- Design pending

- Production pending

- Procurement pending.

- Integrated CRM with Email-to-Lead:

- Integrated CRM with Email-to-Lead:

- Email parsing auto-creates leads.

- Automated brochure sending via Email/WhatsApp.

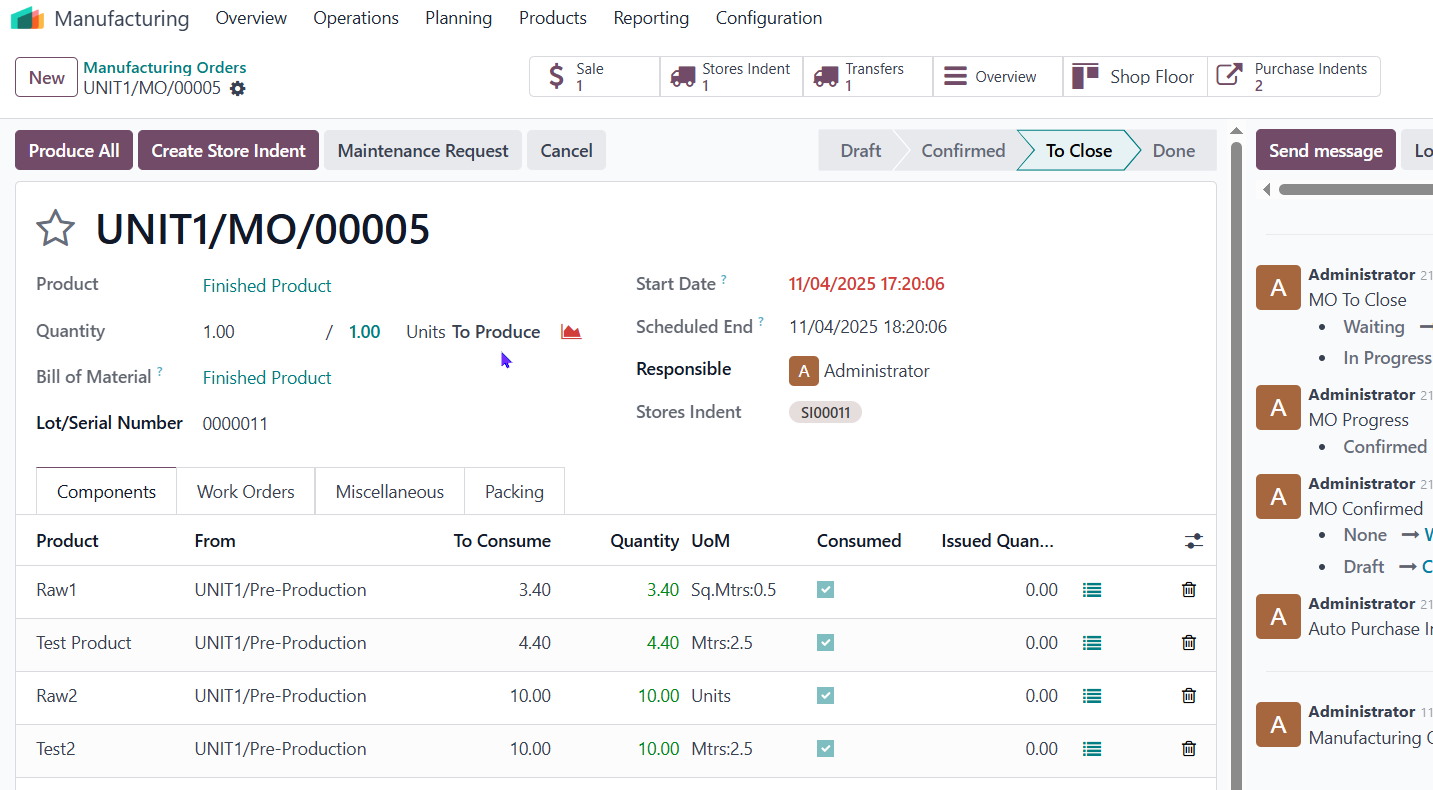

Manufacturing

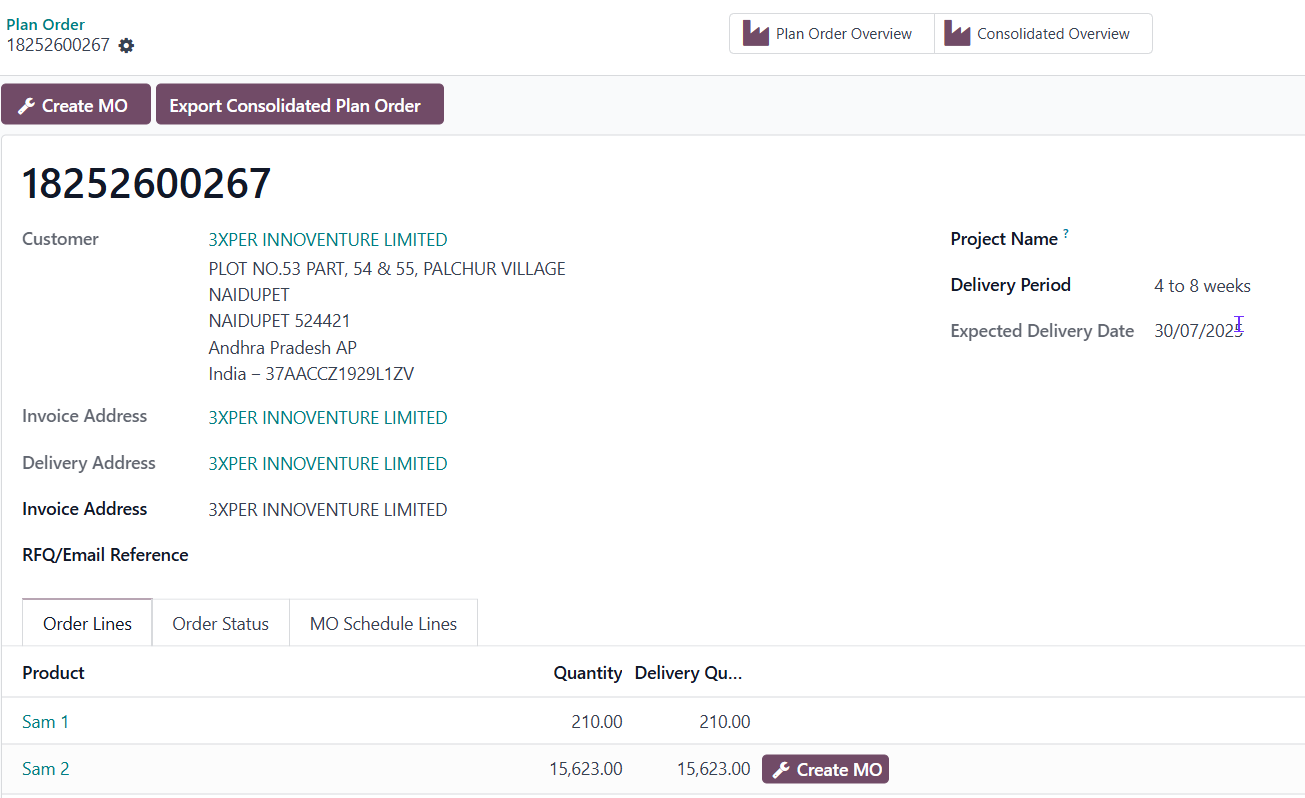

Make to Order Manufacturing:

- Full MO generation based on confirmed Sale Orders.

- LOT/Serial Number Management:

- LOT/Serial Number Management:

- Parent-child MO linkage.

- Serial/Lot generation for Filter Chamber, Mixing Chamber, Coil Chamber & other sub-components.

- FIFO-based material allocation to MOs.

- Shop Floor Integration:

- Shop Floor Integration:

- Odoo Shop Floor module used for work order tracking.

- Fabrication, Painting, and other operations configured as individual Work Orders.

- Non-licensed shop floor users can record operations.

- Special handling for Pashamylaram unit:

- Special handling for Pashamylaram unit:

- Wall & Ceiling Panel production with unique 7-step process.

- Partial manufacturing and shipment upon reaching 350 SQM.

- Custom child MO flow for Panel Sheets (imported via Excel).

- Perishables tracking:

- Perishables tracking:

- Alerts for perishable goods (ink, chemicals) in inventory.

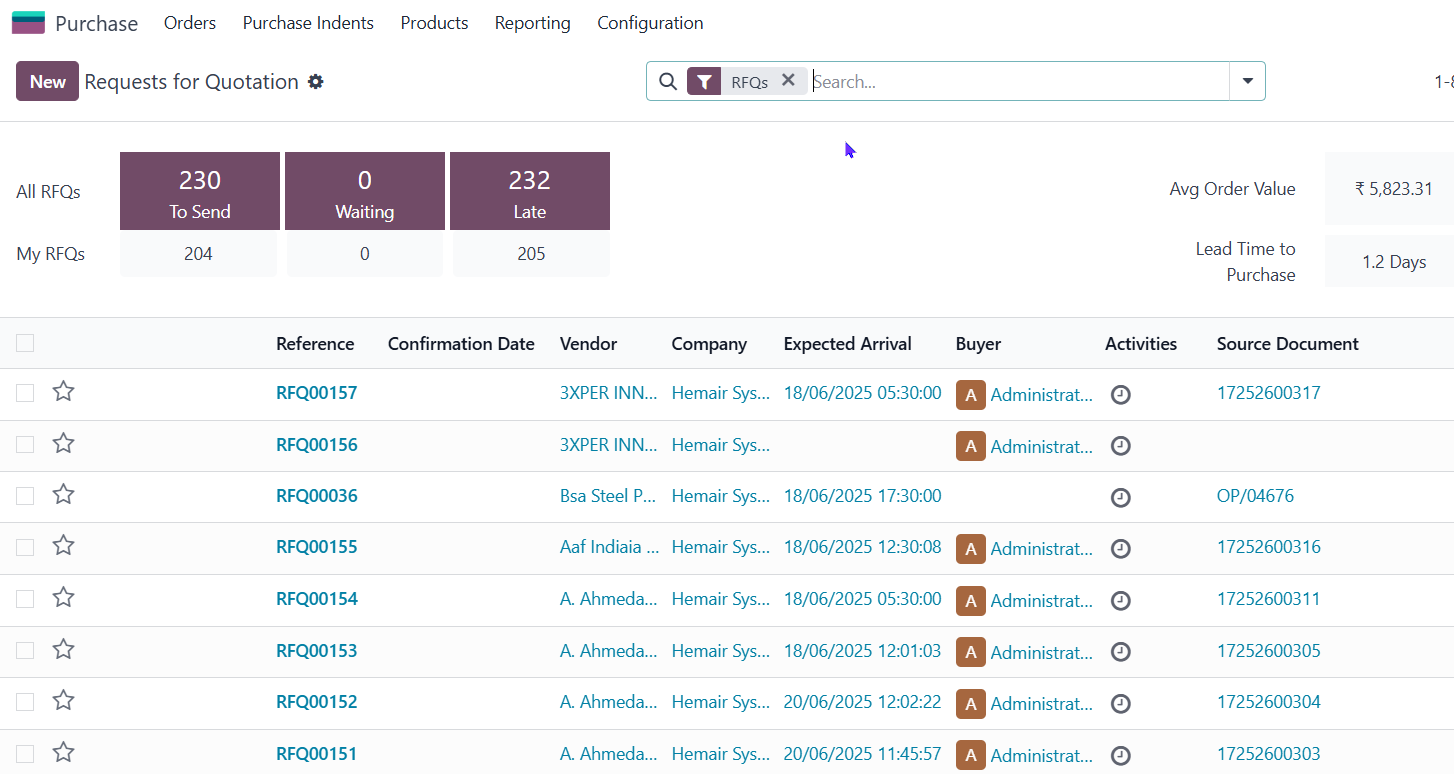

Purchasing & Inventory

- Automated RFQs triggered from Sale Order/Manufacturing need.

- Purchase Info Records for improved pricing control.

- PO output via Email & WhatsApp.

- Goods Receipt process with Quality Control staging.

- Advanced LOT & Serial-based traceability across entire material flow.

- Raw Material Reorder Planning.

- Multi-Warehouse with Location, Aisle, Bin support.

- Cost Center tracking for consumables (Grease, Ink, Paint, etc.) via separate product categories.

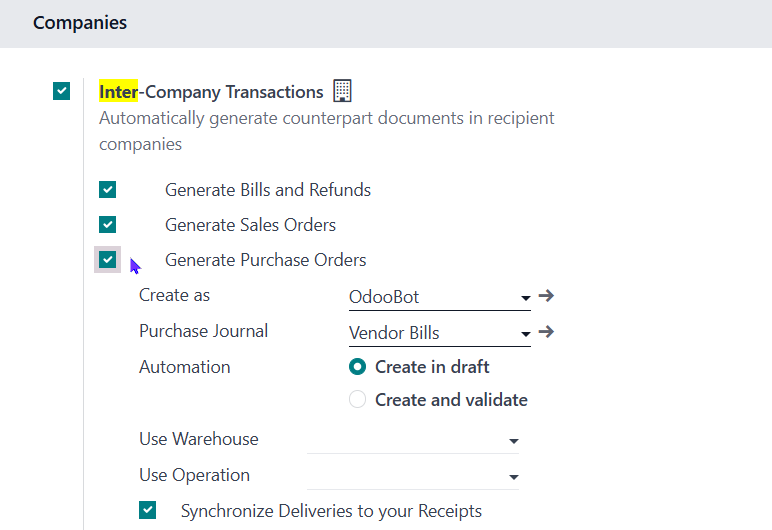

Inter-Company Transactions

Automated flow between Unit 1 & Unit 4 (different GST entities):

- PO + Invoice Bill + E-Invoice generation.

- Delivery Challan process for stock transfers.

- Delivery Challan process for stock transfers.

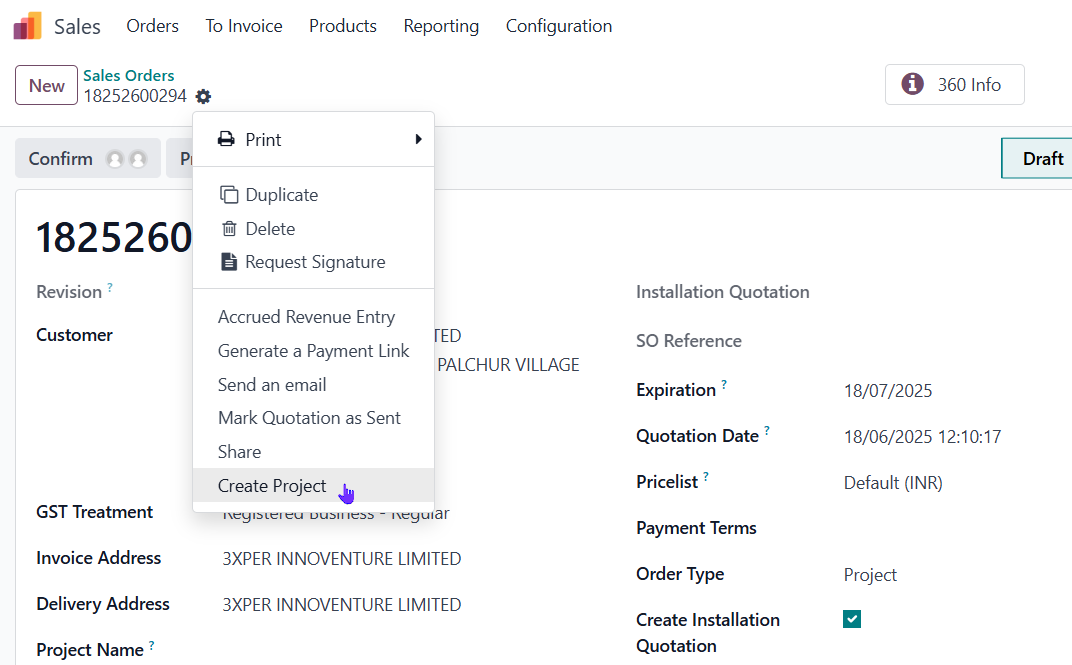

Installation Project Management

- Auto Project creation from Sale Order:

- Project named with Sale Order number.

- Pre-defined tasks & milestones configured based on Product/Category/BOM.

- Installation tasks tracked with actual completion dates.

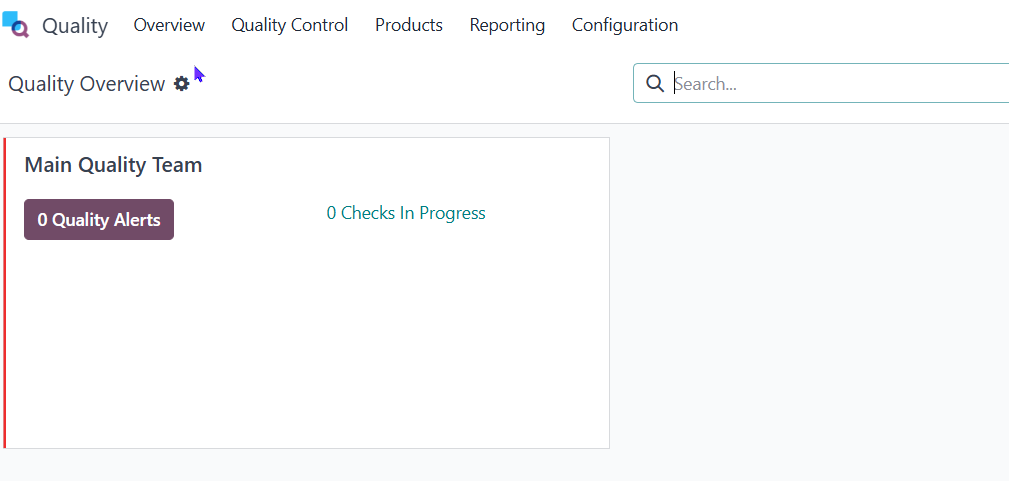

Quality & Maintenance

Quality Management:

- LOT/Serial-based quality tracking.

- Traceability from raw material to finished goods.

- Maintenance Module:

- Maintenance Module:

- Machinery AMC tracking.

- Auto Maintenance Request generation.

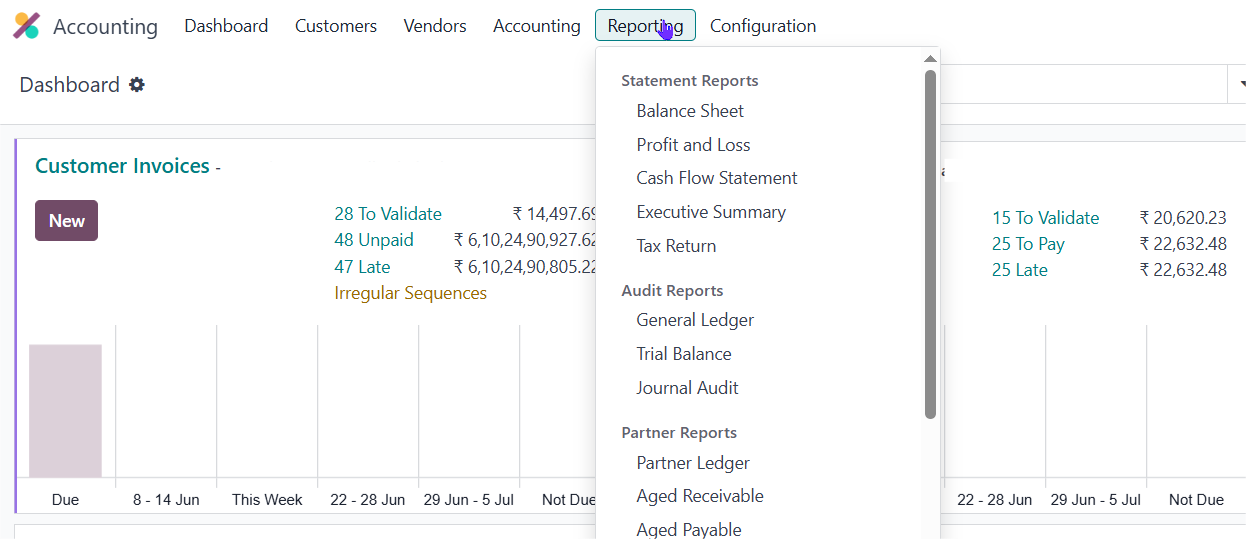

Accounting & Finance

- Manual Journal Entries, Fixed Assets, GL creation.

- GL mapping to Trial Balance & Cost Centers.

- Full plant-wise P&L, Balance Sheet.

- Receipts & Payments with GST handling.

- Clearing Charges tracking for imports.

- Bank Reconciliation automation.

- Comprehensive Reports:

- Balance Sheet

- P&L (company-wise, plant-wise)

- Journal Register

- Fixed Asset Register

- Customer & Currency wise Export Sales Invoice

- Cash Flow Report

- GST Returns.

- Balance Sheet

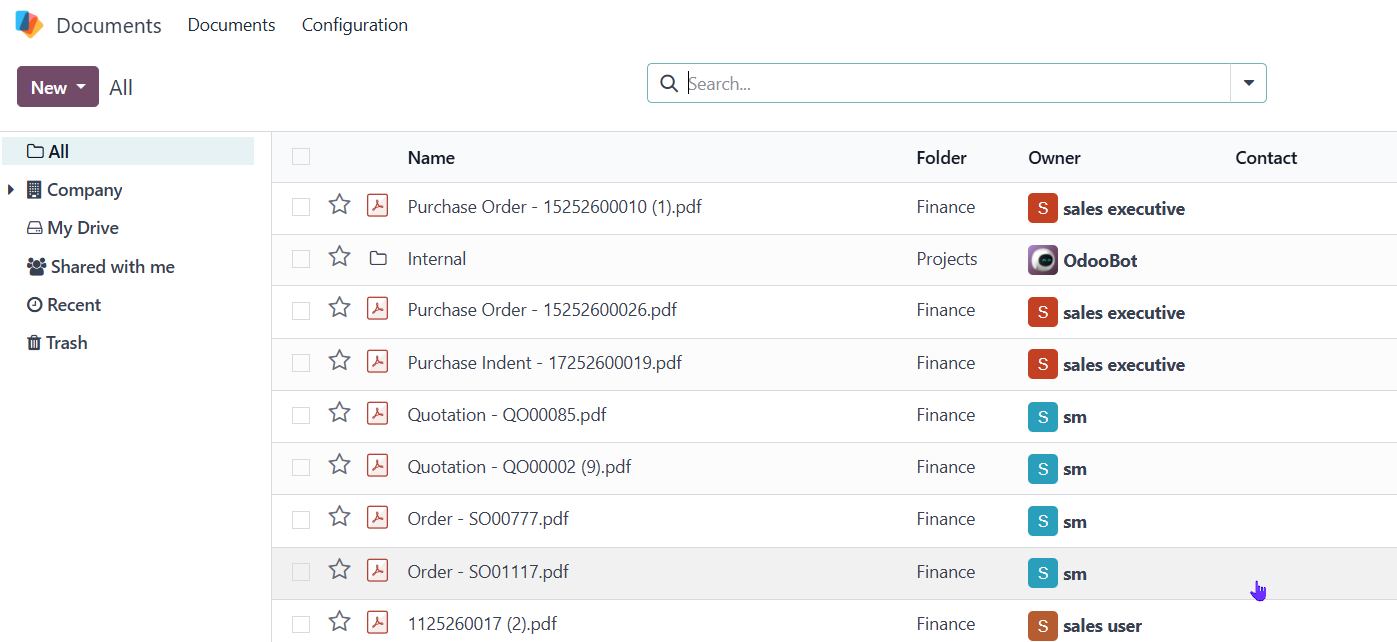

Document Management & Print Customization

- Custom printouts developed for:

- Picking List

- Job Card (Work Order)

- Packing List

- Payslip

- Payment Receipt

- Putaway List

- Production Order (MO)

- Job Offer Letter

- Receivable format.

- Picking List

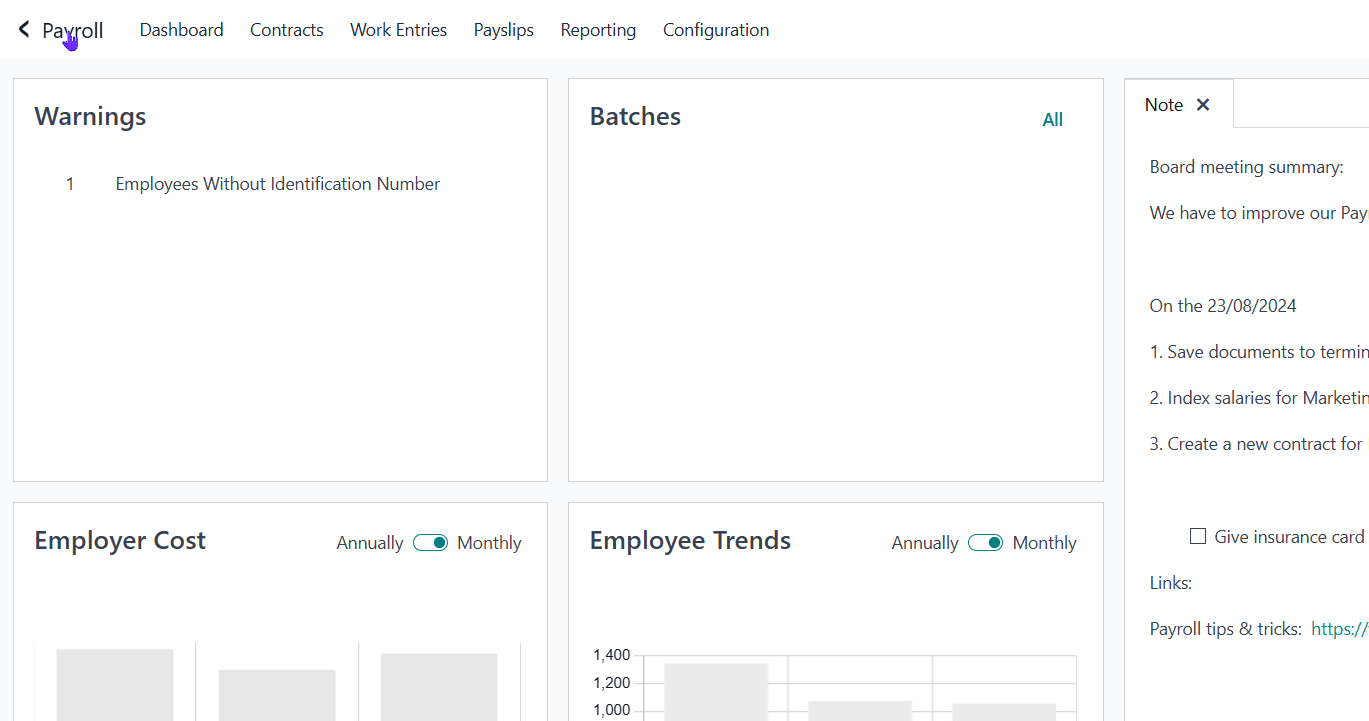

HR & Payroll

- Employee and Contract Management.

- Daily Time Off tracking by HR.

- Payroll planned for future phase (scoping under discussion).

Helpdesk

- Email-to-Ticket setup — incoming emails auto-create Helpdesk tickets.

Outcomes & Business Impact

- Fully automated Sales → Production → Delivery → Installation flow.

- Real-time visibility into Project Milestones and pending actions.

- Inter-company GST processes streamlined.

- Full traceability of critical components across production and inventory.

- Faster and more accurate costing with plant-wise P&L and cost centers.

- CRM pipeline improved with Email-based Lead Capture & automated Brochure dispatch.

- Shop Floor operations digitized without licensing overhead.

- Finance, Inventory & Maintenance unified on a single Odoo 18 Enterprise platform.

Read more about KTree

KTree, a Global IT Company

What and how the processes are structured in KTree?

KTree's processes follow CMMi to ensure consistent, high-quality outcomes. With a focus on quality coding , code reviewing, and performance and load testing in our QA processes, we deliver reliable, scalable, and high-performing applications to meet our clients' needs.

Where is KTree's Web and Mobile application Development done?

KTree's web and mobile application development primarily takes place at our Hyderabad development center. Hyderabad is not only abundant in IT talent but is also known for its rich heritage and exotic food.

How KTree makes outsourcing project a positive experience?

KTree delivers high-quality applications that meet our clients' needs, by prioritizing collaboration, communication, visibility, traceability, and requirements engineering. While we charge a little premium for our services, we believe that it is important to provide the necessary resources and expertise to ensure project success.

What is Success mantra of KTree, as one of the respected web development company?

The success mantra of KTree as a respected web development company is combining Agile methodology with strong documentation, powerful web and mobile frameworks, and a solid KTree team to deliver great web and mobile applications within a specified timeframe.

Any other Differentiation which KTree has, which it can offer?

KTree's tremendous knowledge and expertise, gained from working on hundreds of web and mobile application projects, gives us a significant advantage that allows us to provide a head-start on projects, saving our clients many man-months.

What Development methodology KTree follows and why?

KTree's development team follows the Scrum framework of the Agile methodology, which improves Agility through its simplicity and flexibility. This allows us to adapt to changing project requirements and deliver high-quality products within the specified timeframe.

Partner with a Top Application Development Company

Transform your enterprise with our proven web and mobile solutions. Our expert KTree team delivers results that matter.

Ready to start your project? Let's discuss your needs.

Start Your Project